Makhana Plant | From Seed to Snack | Everything You Need to Know

In this comprehensive guide, we’ll delve into the intricacies of the makhana plant, from seed to snack, and discover why it has become a beloved choice for health-conscious individuals and food connoisseurs alike.

In the world of healthy and delectable snacks, the humble makhana has gained remarkable prominence in recent years. But makhana is more than just a delicious snack; it has a fascinating journey from its origin as a humble seed to its transformation into a delightful munchable.

What is the Makhana Plant? | Where does Makhana Grow?

Derived from the seeds of the prickly water lily plant (Euryale ferox), makhana has been an integral part of traditional cuisines and Ayurvedic practices for centuries. The water lily plant is sometimes commonly referred to as the makhana plant. Makhana is primarily composed of the seeds of the water lily plant, which are carefully harvested and processed to retain their inherent nutritional goodness. These makhana seeds are then dried, revealing their delicate and puffed appearance, resembling small foxes, thus earning them the name “Fox Nuts”.

While makhana is cultivated in countries such as India, China, Japan, and Korea, certain estimates suggest that about 90% of world cultivation happens in Bihar (India).

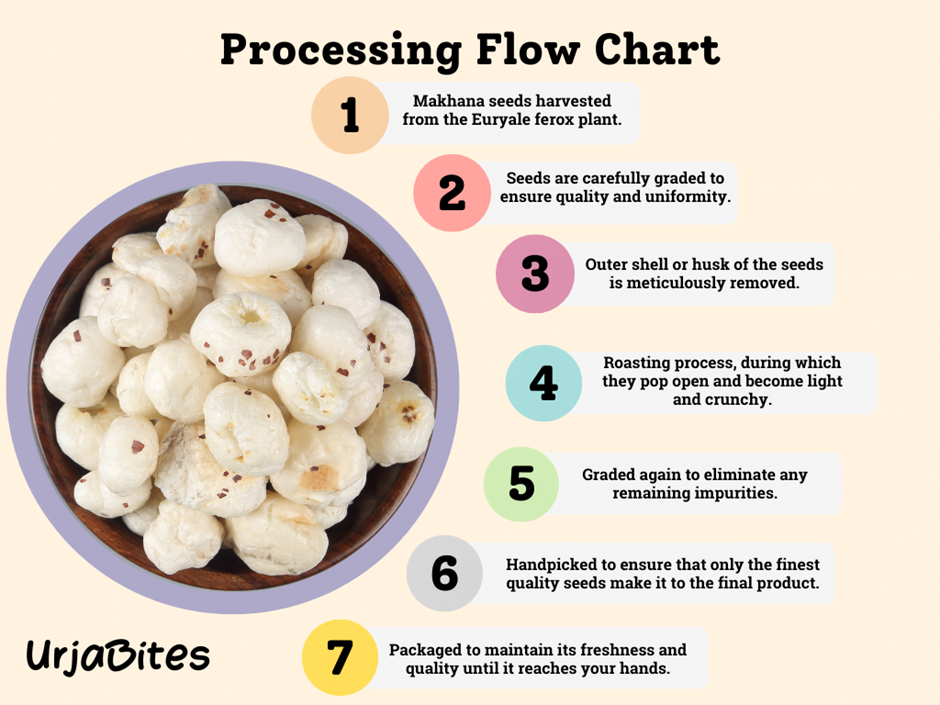

Makhana Plant Processing

Step 1: Harvesting and Collection

The journey of Makhana (fox nuts in Hindi) begins amidst the tranquil beauty of ponds and water bodies which are home to the Euryale Ferox plant, sometimes also referred to as the Makhana plant. It is a perennial aquatic plant that grows in ponds, lakes, and other still-water bodies. The large lotus-like leaves and small white flowers from this plant are often why people confuse this plant with the lotus plant and refer to makhana seeds as lotus seeds. The seeds of the plant are the Makhana seeds. These Makhana seeds are harvested from this plant when they are ripe, which is usually in the months of September and October. The ripe seeds are brown and slightly translucent. There are two main methods of harvesting makhana seeds:

- Divers: Divers are used to harvest the seeds from deeper water. They swim down to the bottom of the water body and collect the seeds by hand.

- Bamboo pole: The bamboo pole method is used for shallower water. A bamboo pole with a net attached to the end is used to sweep the bottom of the water body and collect the seeds.

Once the seeds have been harvested, they are collected in baskets and taken to the processing plant.

Below are some additional details about the harvesting and collection process:

Harvesting time: The best time to harvest makhana seeds is in the morning when the water is calm, and the seeds are easier to see.

Harvesting depth: The depth of the water where the makhana seeds are harvested depends on the method being used. Divers can harvest seeds from depths of up to 10 meters, while the bamboo pole method is only effective in shallow water.

Harvesting yield: The yield of makhana seeds depends on several factors, including the age of the plant, the water quality, and the weather conditions. In general, a mature makhana plant can produce up to 10 kilograms of seeds per year.

Step 2: Cleaning and Removal of the Outer Layer

After the fox nuts seeds have been harvested, they are taken to the processing plant where they are cleaned, so that the outer layer can be removed. These seeds are encased in an outer layer, often referred to as the “skin” or “husk.” This outer layer of the makhana seed is a tough, fibrous material that is not edible. It is removed by hand or by using a machine.

- The hand-peeling method is the traditional method of removing the outer layer. The seeds are placed in a large bowl and then workers carefully peel off the outer layer, one seed at a time. This is a slow and labour-intensive process, but it is the gentlest way to remove the outer layer without damaging the seed.

- The machine-peeling method is a more efficient way to remove the outer layer. This method is faster than the hand-peeling method, but it can damage the seeds if it is not done carefully.

Once the outer layer has been removed, the seeds are washed to remove any dirt or debris. The aim is not only to expose the inner edible portion but also to ensure that the Makhana seeds are free from any impurities or remnants of the seedpod.

Step 3: Drying Under Sunlight

After the outer layer has been removed, the makhana seeds are spread out in open and well-ventilated spaces to dry in the sun.

The sun-drying process serves two purposes:

- To remove moisture: The sun-drying process removes any residual moisture from the seeds, preventing the growth of Mold or Fungi. This is important because moisture can cause the seeds to spoil.

- To impart a natural crispiness: The sun-drying process also imparts a natural crispiness to the seeds. This is a hallmark of well-prepared phool makhana.

The sun-drying process is a delicate one. The seeds must be spread out evenly so that they dry evenly and must also be protected from rain and wind.

- Sunlight: The sun’s rays help to evaporate the moisture from the seeds. The ideal sunlight is bright and warm, but not too hot.

- Airflow: The seeds must be spread out in a way that allows for airflow. This helps to prevent the growth of Mold or Fungi.

- Time: The sun-drying process takes several days, depending on the weather conditions. The seeds are typically dried for 2-3 days in direct sunlight.

- Quality control: The quality of the makhana seeds is closely monitored throughout the sun-drying process.

Step 4: Roasting & Popping

The dried phool makhana seeds are roasted in a pan over medium-low heat to produce roasted makhana. As the seeds make contact with the heat, they pop open and become light and crunchy. This process takes about 10-15 minutes, depending on the size of the seeds and the heat of the pan.

The key to roasting makhana evenly is to use medium-low heat and to stir constantly. If the heat is too high, the makhana will burn. If the heat is too low, the roasted makhana will not puff up properly.

Here are some additional tips for roasting makhana:

- Use a heavy-bottomed pan to prevent the makhana from sticking.

- Add a small amount of ghee or oil to the pan to prevent the makhana from sticking.

- Stir the makhana constantly to ensure that they roast evenly.

- Roast the makhana until they are golden brown and puffed up.

- Do not over-roast the makhana, or they will become hard.

Once the roasted makhana flakes are produced, they are removed from the pan and cooled.

Step 5: Grading & Sorting

Grading is the process of sorting roasted makhana flakes into different sizes. This is done using a series of sieves with different mesh sizes. The sieves are stacked one on top of the other, with the largest sieve at the top and the smallest sieve at the bottom. The makhana flakes are poured into the top sieve, and the seeds that are too small to fit through the mesh fall into the next sieve. This process is repeated until all the makhana flakes have been sorted into different sizes. Below are a few reasons why grading is important:

- First, it ensures that the makhana flakes are of uniform size. This is important as the size of makhana flakes also determines makhana price.

- Second, grading helps to remove any impurities from the makhana flakes. This includes broken flakes, seeds that are not fully popped, and any other foreign objects.

The grading process is usually done by hand, but there are also machines that can be used. The machines use a series of vibrating screens to sort the makhana flakes.

Here are some additional details about the grading process:

- Sieves: The sieves used for grading makhana flakes are typically made of metal or plastic. The mesh size of the sieves depends on the desired size of the makhana flakes.

- Hand grading: The traditional method of grading makhana flakes is by hand. The seeds are poured into a series of sieves, and the workers sort the flakes by hand.

- Machine grading: There are also machines that can be used to grade makhana flakes. These machines use a series of vibrating screens to sort the flakes. This is a faster and more efficient way to grade the flakes, but it is not as accurate as hand grading.

- Quality control: The quality of the makhana flakes is closely monitored throughout the grading process.

Step 6: Hand-picking (Optional)

Handpicking is the process of removing any impurities from the makhana flakes by hand. This includes broken flakes, seeds that are not fully popped, and any other foreign objects.

Handpicking is usually done by women who are trained to identify and remove impurities. The women sit at tables and sort through the makhana flakes, removing any impurities that they find.

Here are some interesting details about the handpicking process:

- Tools: The tools used for handpicking makhana flakes are typically tweezers and a magnifying glass. The tweezers are used to remove the impurities, and the magnifying glass is used to help the workers see the impurities more clearly.

- Skill: The skill of the hand-picker is important for the quality of the makhana flakes. The hand-pickers need to be able to identify and remove impurities quickly and accurately.

- Quality control: The quality of the makhana flakes is closely monitored throughout the handpicking process.

Here are some of the benefits of handpicked makhana:

- Higher quality than machine-picked makhana.

- Free from impurities.

- Have a better taste and texture.

At UrjaBites, we take pride in our rigorous hand-picking process for both varieties of Makhana: Jumbo & Premium. This approach is a cornerstone of what sets our product apart in a competitive market, where a lot of the Makhana being sold is not hand-picked.

Step 7: Packaging & Storage

Once the makhana flakes have been graded and hand-picked, they are packaged in airtight containers to preserve their texture, taste, and quality.

The right packaging of makhana flakes protects them from moisture, oxygen, and light. Otherwise, the seeds can lose their crispiness and flavor. The packaging material used for makhana flakes is typically plastic or glass and they are packed in tightly sealed containers.

The makhana flakes are then labeled with the name of the product, the weight, and the expiration date. They are then ready for storage and shipping.

Here are some additional details about the packaging process:

- Packaging material: The packaging material used for makhana flakes is typically plastic or glass. Plastic is more economical, but glass is more durable and can protect the flakes from light better.

- Labelling: The makhana flakes are labeled with the name of the product, the weight, and the expiration date. The expiration date is typically 6 months to 1 year from the date of packaging.

- Storage: Makhana flakes can be stored in a cool, dry place for up to 1 year.

Conclusion

In this comprehensive exploration of the makhana plant, we’ve ventured from its origins as the seeds of the prickly water lily plant to the delightful snack loved by many. We’ve followed its remarkable journey, from the serene waters where it thrives to the processing plant where its transformation begins.

The makhana plant’s journey is a testament to the dedication and craftsmanship involved in bringing this wholesome snack to our tables. As we’ve seen, skilled divers and harvesters carefully gather the ripe seeds from the aquatic habitats, ensuring a bountiful yield of these unique fox nuts.

Once harvested, the meticulous process of cleaning, husk removal, sun-drying, roasting, grading, and hand-picking, when needed, ensures that only the finest makhana flakes make their way to our homes. As we conclude our journey through the world of the makhana plant, we’re left with a newfound appreciation for this versatile and health-conscious snack.

So, the next time you reach for a bowl of makhana, remember the fascinating journey it undertook from its humble origins to become the beloved snack it is today.

Is there a particular season during which makhana is harvested?